Parameters

| Single pump weight |

960kg |

| Single pump shape | 1600X950X620(mm) |

| Maximum pressure | 280Mpa |

| Maximum flow | 1020L/min |

| Rated shaft power | 250KW |

| Optional speed ratio | 3.5:1 4.09:1 4.62:1 5.21:1 |

| Recommended oil | Shell pressure S2G 220 |

Product Details

Features

1. High pressure pump adopts forced lubrication and cooling system to ensure long-term stable operation of power end;

2. The crankshaft box of the power end is cast with ductile iron, and the cross head slide is made of cold-set alloy sleeve technology, which is wear-resistant, low noise and compatible high precision;

3. Fine grinding of gear shaft and gear ring surface, low running noise; Use with NSK bearing to ensure stable operation;

4. The crankshaft is made of American standard 4340 high quality alloy steel, 100% flaw detection treatment, forging ratio 4:1, after survival, the whole nitriding treatment, compared

Traditional 42CrMo crankshaft, strength increased by 20%;

5. The pump head adopts high-pressure/water inlet split structure, which reduces the weight of the pump head and is easier to install and disassemble on site.

6. The plunger is tungsten carbide material with hardness higher than HRA92, surface accuracy higher than 0.05Ra, straightness and cylindricity less than 0.01mm, both

Ensure hardness and wear resistance also ensure corrosion resistance and improve service life;

7. The plunger self-positioning technology is used to ensure that the plunger is stressed evenly and the service life of the seal is greatly extended;

8. The stuffing box is equipped with imported V-type packing to ensure the high pressure pulse of high pressure water, long life;

Application Areas

★ Traditional Cleaning (Cleaning Company)/Surface Cleaning/Tank Cleaning/Heat Exchanger Tube Cleaning/Pipe Cleaning

★ Paint Removal From Ship/Ship Hull Cleaning/Ocean Platform/Ship Industry

★ Sewer Cleaning/Sewer Pipeline Cleaning/Sewer Dredging Vehicle

★ Minning, Dust Reduction By Spraying In Coal Mine, Hydraulic Support, Water Injection To Coal Seam

★ Rail Transit/Automobiles/Investment Casting Cleaning/Preparation For Highway Overlay

★ Construction/Steel Structure/Descaling/Concrete Surface Preparation/Asbestos Removal

★ Power Plant

★ Petrochemical

★ Aluminium Oxide

★ Petroleum/Oil Field Cleaning Applications

★ Metallurgy

★ Spunlace Non-Woven Fabric

★ Aluminium Plate Cleaning

★ Landmark Removal

★ Deburring

★ Food Industry

★ Scientific Research

★ Military

★ Aerospace, Aviation

★ Water Jet Cutting, Hydraulic Demolition

Recommended working conditions:

Heat exchangers, evaporation tanks and other scenarios, surface paint and rust removal, landmark cleaning, runway degumming, pipeline cleaning, etc.

Cleaning time is saved due to excellent stability, ease of operation, etc.

It improves efficiency, saves personnel costs, liberates labor, and is simple to operate,and ordinary workers can operate without training.

(Note: The above working conditions need to be completed with various actuators, and the purchase of the unit does not include all kinds of actuators, and all kinds of actuators need to be purchased separately )

FAQ

Q1. What pressure and flow rate of the UHP water blaster usually the shipyard industry used?

A1. Usually 2800bar and 34-45L/M the most used in the shipyard cleaning.

Q2. Does your ship cleaning solution hard to operate?

A2. No, it is very easy and simple to operate, and we support online technical, video, manual service.

Q3. How do you help to solve the problem if we met when operation on working site?

A3. First, response quickly to deal with the problem you met. And then if it is possible we can be your working site to help.

Q4. What is your delivery time and payment term?

A4. Will be 30days if have in stock, and will be 4-8weeks if don't have stock. The payment can be T/T. 30%-50%deposit in advance, the rest balance before delivery.

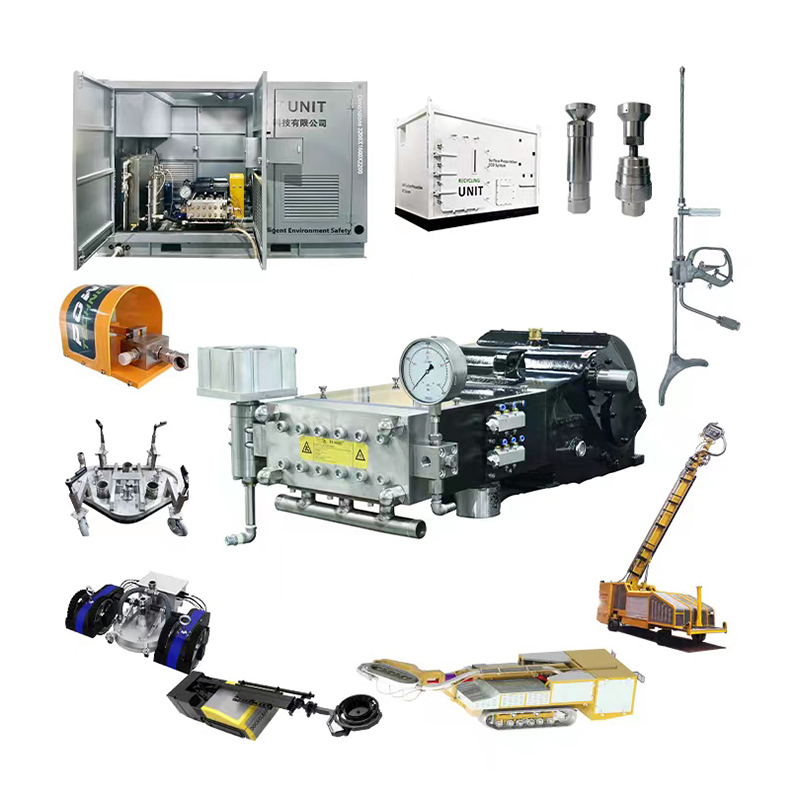

Q5.、What can you buy from us?

A5、Ultra high pressure pump set,High pressure pump set,Medium pressure pump set, Large remote control robot,Wall climbing remote control robot.

Q6. Why should you buy from us not from other suppliers?

A6. Our company has 50 proprietary intellectual property rights. Our products have been long-term verified by the market, and the total sales volume has exceeded 150 million yuan.The company has independent R&D strength and standardized management.

In all cases we will try to accommodate your needs. In most cases we are able to do so.

Description

One of the key features of our high-pressure pump is its forced lubrication and cooling system. This innovative system ensures that the power end of the pump operates smoothly and reliably for a long period of time. With this pump, you can expect stable performance, even under the most demanding conditions.

The power end of our pump is built to last. The crankshaft box is cast with ductile iron, providing exceptional strength and durability. Additionally, the cross head slide is made using cold-set alloy sleeve technology, which offers wear-resistance and low noise operation. With its high precision design, you can depend on this pump to deliver accurate and consistent results.

We have paid attention to every detail in designing this pump. The gear shaft and gear ring surfaces are finely ground, resulting in low running noise. To further enhance the performance and reliability of our pump, we have chosen to use NSK bearings. By utilizing these high-quality bearings, we can ensure that the pump operates smoothly and without any issues.

In addition to its superior performance, our high-pressure pump is also compact in size. This makes it easy to install and integrate into your existing liquid processing system. Its horizontal triple plunger design also contributes to its compactness, while still delivering a high level of power.

With a maximum pressure of 2800 bar, our high-pressure pump is capable of handling even the toughest liquid processing tasks. Whether you need to pump chemicals, oils, or any other liquids, this pump will get the job done efficiently and effectively.

Company Information:

Power (Tianjin) technology Co., Ltd. is a high-tech enterprise integrating R&D and manufacturing of HP and UHP water jet intelligent equipment, cleaning engineering solutions, and cleaning. The business scope involves many fields such as shipbuilding, transportation, metallurgy, municipal administration, construction, petroleum and petrochemical, coal, electric power, chemical industry, aviation, aerospace, etc. Production of various types of full automatic and semi-automatic professional equipments.

In addition to company headquarters, there are overseas offices in Shanghai, Zhoushan, Dalian, and Qingdao. The company is a nationally recognized high-tech enterprise. Patent achievement enterprise.and also is member units of multiple academic groups.

Quality Test Equipment:

Workshop Display:

Exhibition:

With a maximum pressure of 2800 bar, our pumps are capable of handling even the toughest liquid handling applications. Whether it’s high pressure washing, water blasting or chemical blasting, our pumps deliver exceptional power and performance time and time again.

But that’s not all. Our pumps are also available in a convenient horizontal design that can be easily installed and integrated into existing systems. The compact size further increases versatility, making it suitable for a wide range of industries and applications.

-

Construction plunger pumps high pressure and fl...

-

High pressure plunger pump with competitive pri...

-

Environmental protection compact structure hori...

-

Made in China hot sale high pressure horizontal...

-

Commercial high pressure water jet cleaning sys...

-

Water blasting machine plunger pumps high press...